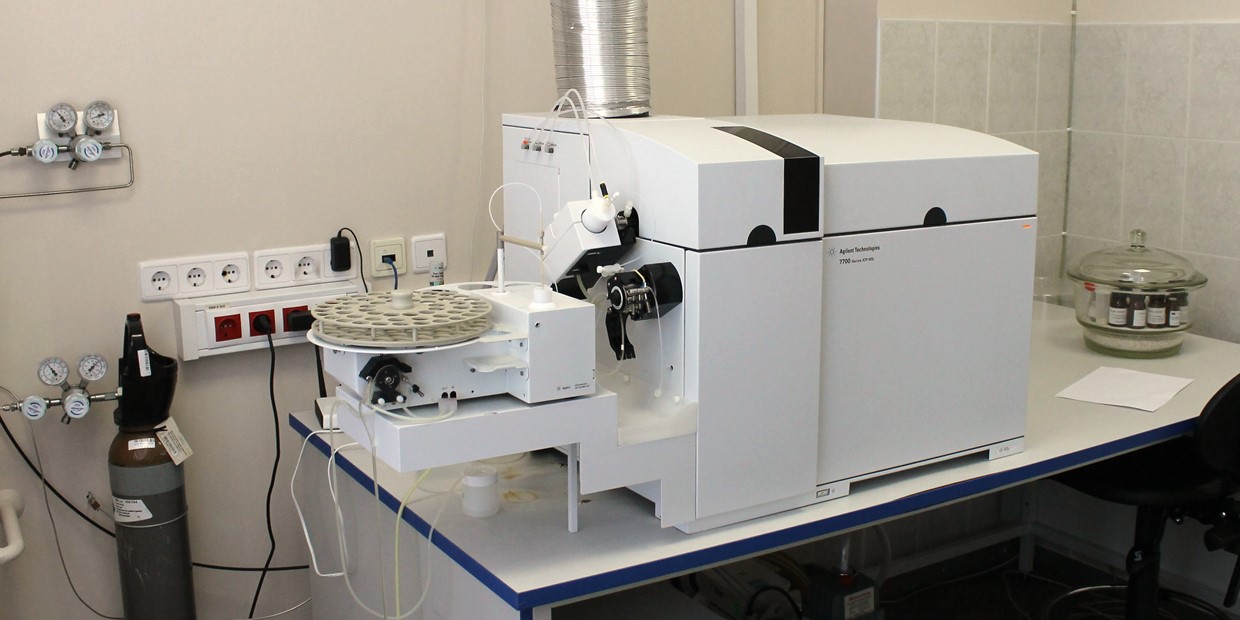

Powerstroke engines equipped with Ford models must have ICP sensors. You need to be familiar with the ICP sensor, which is in Ford powerstroke engines, and understand how it works.

Table of Contents

What is the ICP Sensor?

Engines are equipped with sensors that measure injection pressure. Fuel delivery is adapted according to the conditions of this sensor so that the vehicle can deliver fuel at the appropriate time.

The process is as follows.

The 7.3 ICP Sensor operates on an analog signal. In cars, sensors detect pressure caused by factors like load, road conditions, and driving speed. Signals will be sent from the sensors indicating how much fuel the vehicle needs in order to run smoothly. When the vehicle has received the appropriate fuel delivery, it can continue running normally.

Importance of Maintenance

The ICP sensors on Ford vehicles need to be maintained regularly. If the powerstroke motor is not receiving strong signals or if communication is not effective, it can cause a variety of problems.

Fuel delivery efficiency can be increased by measuring ICP. When the sensor malfunctions, you may notice improper fuel flow. In some instances, the proximity sensor may have to be repaired or replaced.

ICP sensors are used in Ford powerstroke vehicles to detect overheating. As a result of pressure readings during driving, fuel is delivered. A vehicle performs at its best when it is properly maintained.

Understanding ICP Sensor Bias is Beneficial

In order to power ICP sensors, a DC supply ranging from 18 to 28 volts must provide a constant current of 2 to 20 mA. Most applications require a power supply between two and four milliamFor cables over 100 feet (>100 ft) and with high frequencies (>100 kHz), currents must be higher to prevent attenuation of the high frequency. To learn more about ICP sensors over long cables, view the reference nomograph.

DC voltage directly applied to the electrode without a power supply or voltage meter can damage the internal electronics of the sensors.

When you use the DMM to measure the ICP Sensor’s resistance to the ground, you will not achieve meaningful results. Follow the instructions below to prevent damaging the sensor’s electronics.

There may be a bias voltage or other special tool available in the newer ICP sensors to check the sensor’s performance, such as a biased LED indicator.

For an ICP sensor connected by a good cable, the bias voltage is normally 9 to 13V (Mid Green), lower (3 to 8 V) for low bias sensors (such as seismic and cryogenic sensors), or high (14 to 17 V) for sensors with circuit gain.

In comparison, longer discharge times (long discharge times) are associated with higher range pressure and force sensors. After a few minutes, power should be applied to the sensor. Modern dynamic sensors typically have welded cases and glass-filled connectors that ensure hermetic sealing. Sensors that are showing signs of bias failure (for example, if they have been inactive for an extended period of time) can be retested overnight by heating at 225°F (or less depending on the sensor’s temperature rating).